What are the main differences between chipboard vs MDF? Dive into the world of engineered wood with our guide on Chipboard vs MDF - unraveling the main differences. Understand the distinct characteristics, applications, and advantages of both chipboard and medium-density fiberboard (MDF).

What Is Chipboard, And When Is It Used?

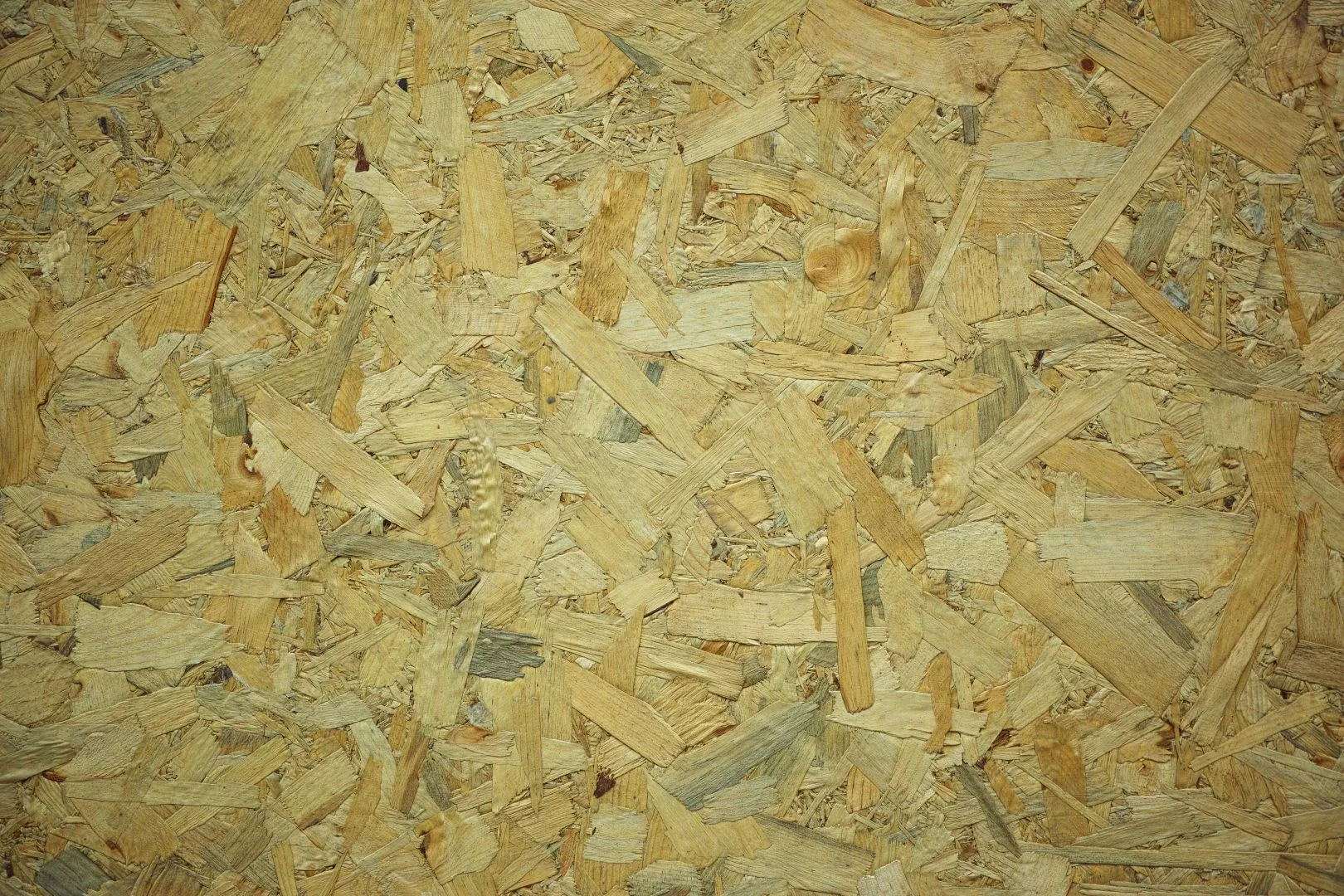

Chipboard, known in some places as particleboard, is an engineered wood that has been steadily rising in popularity due to its versatility. Created by tightly compressing wood chips, sawdust, and a resin that acts as a binding agent under immense pressure, the chipboard boasts an even density throughout its structure. This feature proves extremely beneficial and advantageous in a variety of scenarios.

A prime choice in the furniture industry, chipboard is favoured for its economic value, ease of workability, and the simplicity with which it can be decorated. Its unique combination of robust strength, manageable weight and affordable cost renders it perfect for wardrobes, bookcases, desks and flat-packed furniture. Besides furniture, chipboard is also in demand for flooring, wall linings, and the creation of kitchen units and worktops.

Worth noting is that chipboard is not one-size-fits-all; there are different kinds such as standard, melamine-faced, and veneered. The choice of chipboard should correspond with the requirements of your specific project as each variant has its own distinctive attributes.

For instance, melamine-faced chipboard is typically employed for the making of cabinets and furniture. This is because it has a coating that endows it with resistance against moisture, thereby enhancing its durability. Therefore, whether you're building a bookcase or constructing kitchen cabinets, there is a chipboard perfectly suited to your needs.

What Is MDF And What Is It Used For?

Medium Density Fibreboard, or MDF, stands out among the various types of engineered wood available in today's market. This material, unlike chipboard which utilises wood chips, is created by dismantling hardwood or softwood residues into fine wood fibres.

These fibres are methodically combined with a binder resin and then transformed into panels through the application of high temperature and pressure. This manufacturing process delivers a product with a considerably higher density than chipboard. The resulting robust and durable character of MDF makes it an ideal choice for a host of applications – from crafting cabinets and furniture bits to creating decorative mouldings.

The strength of MDF ensures that it can reliably bear the weight of screws and nails without experiencing damage or deterioration. Moreover, thanks to its smooth surface, this engineered wood material lends itself well to different finishes, be it painting or veneering.

One of the noteworthy properties of MDF is its ability to be shaped easily, without any risk of splintering. With this inherent flexibility, MDF can indeed be fashioned into a range of intricate decorative mouldings. This has made it a popular choice among craftsmen, designers, and hobbyists alike.

Just as with chipboard, MDF is available in a plethora of variants to cater to the specific needs of various projects. These include moisture-resistant forms, providing durability even in high-humidity environments; fire-retardant versions, which offer an extra layer of safety in fire-prone settings; and ultra-light types that are easier to handle and install. Choosing the right type of MDF board is critical to ensure its optimal performance and longevity.

It depends immensely on the requirements of the project at hand, as well as the environment where it will be utilised. Hence, it's advised to take these factors into account upon selecting the perfect MDF board for your venture. In conclusion, the strength, versatility and selection of variants make MDF a great choice for a multitude of indoor woodworking projects, providing superior quality and durability over time.

Is MDF More Durable Than Chipboard?

When discussing the resilience of chipboard versus MDF (Medium Density Fibreboard), it is generally agreed that MDF often comes out on top. There are several reasons for this: the main attribute is its increased density and finer surface, which gives it noteworthy physical strength. This means it can handle day-to-day wear and tear a little better than its chipboard counterpart.

Another strong point in favour of MDF is its screw and nail-holding abilities. Unlike some other materials, MDF does not tend to split or crack easily when screws and nails are embedded. This gives it an added edge of robustness, proving particularly beneficial in situations such as furniture assembly, where the material requires constant and demanding manipulation.

However, it's key to bear in mind that both MDF and chipboard, despite their strengths, have a shared weakness in the form of water exposure. Neither material can withstand prolonged contact with water. Too much moisture can cause them to swell, distort, and ultimately become unfit for purpose. This is a significant concern, especially during installation.

To mitigate this issue, care should be taken to minimise water contact. Alternatively, using moisture-resistant versions of these materials can be a good way to ensure higher longevity of your installations. In conclusion, while having respective merits, the inherent characteristics of MDF usually render it a more durable selection as compared to chipboard.

Is Chipboard Or MDF Cheaper?

Chipboard is a popular construction material due to its lower cost, which can depend on factors like the quality, thickness, or the type of facing applied to it. This material is often used in the manufacturing process of cost-effective furniture and shelving units due to its affordability - making it a budget-friendly option for many projects. However, it is crucial to note that despite its lower cost, chipboard may not always be the most cost-effective choice, particularly for projects requiring longevity and durability. This is where Medium Density Fibreboard (MDF) comes in.

Although MDF tends to be more expensive, it offers increased durability, meaning that it could provide better value for certain project requirements in the long run. This robust material is less susceptible to damage, making it an ideal choice for projects where long-term durability is a top priority. Selecting the correct material for your project is of paramount importance. Therefore this choice should never be based solely on immediate financial constraints.

A comprehensive evaluation of the project's needs, budget, and long-term durability requirements will provide the true value of each material. So, consider carefully between chipboard and MDF when embarking on your next project. While initial costs may differ, it's essential to consider the long-term value and durability each material provides. Remember, the right choice can make all the difference to your project's success.

Should I Use MDF Or Chipboard?

When embarking on a project, deciding on materials is a significant first step. One common dilemma is whether to opt for a chipboard or MDF (Medium Density Fibreboard). The answer, as with many things, lies in the specifics of your project requirements - it's not a decision with a standard, universal answer. MDF and chipboard are both types of engineered wood, popularly used in various types of construction and DIY projects.

Your choice between these two materials may depend on a number of key factors, revolving around the intended use of the final product. When toughness and durability are vital considerations, a medium-density fibreboard could be the optimal choice over a chipboard. This material is denser and generally stronger, making it particularly suitable for projects that need to withstand heavy use or load, such as shelves or cabinets for heavy items.

However, affordability might be the crucial determinant in your material decision. In such a scenario, your project could benefit more from using chipboard. This material, made out of compressed wood chips and resin, is usually cheaper than MDF.

Chipboard proves to be the optimal choice, particularly for lighter-duty furniture, such as items in a child's bedroom or a seldom-used guest room, where the lower durability compared to MDF isn't an issue. For projects that would be exposed to a damp or humid environment, both chipboard and MDF come with their own challenges.

However, there are moisture-resistant variants available for both materials, treated specially to withstand damp conditions better than their standard versions. Therefore, when dealing with moisture exposure, a more thorough cost-and-benefit analysis might be valuable.

In conclusion, there is plainly no one-size-fits-all answer in the Chipboard Versus MDF debate. Each material comes with its distinct strengths and weaknesses. The right choice is heavily dependent on multiple factors including the specific requirements of your project, cost constraints, and the anticipated level of usage and environmental exposure of the final product. The careful evaluation of these factors is crucial to make the best possible decision.

Are you looking for chipboard timber delivery in Manchester and the surrounding areas? We offer a range of timber cut to size for Manchester, Liverpool, Preston, Oldham, Stockport, Warrington and the surrounding areas.